-

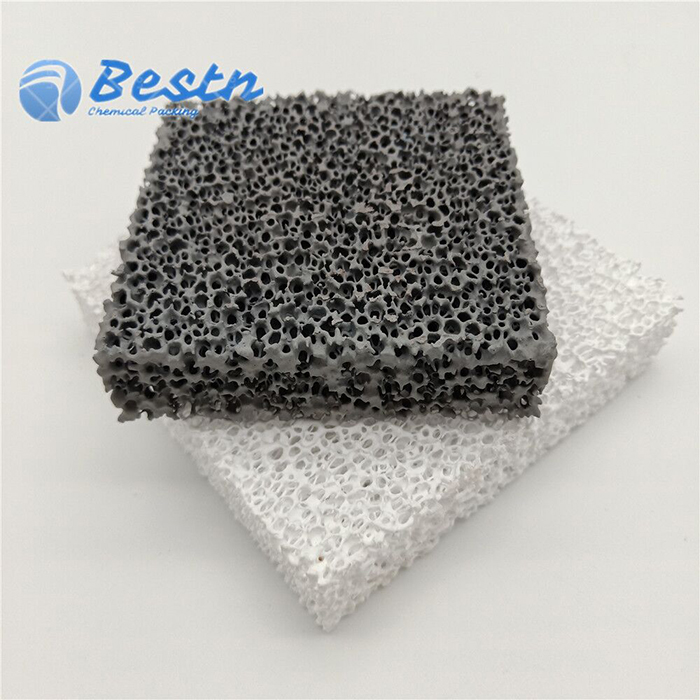

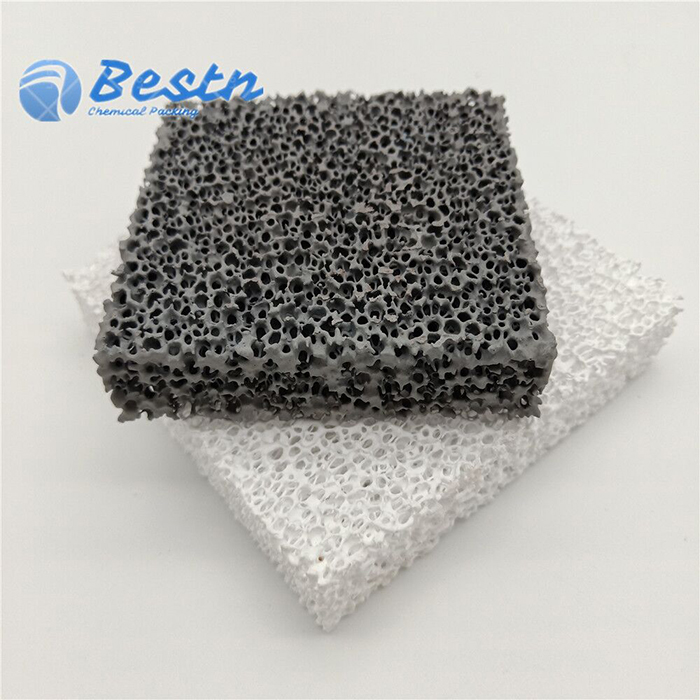

Newly Arrival 8-60ppi Silicon Carbide Foam Ceramic Filter Media for Molten Metal Filtration and Low Pressure Casting

Silicon Carbide Ceramic Foam Filters mainly for filtration of cast iron and non-ferrous alloys. With their excellent resistance to attack and corrosion from molten iron liquid, they can effectively remove inclusions, reduce trapped gas from liquid metal and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit. SiC Ceramic Foam Filters is available in all standard dimensions and different thickness. The most common porosities are PPI 10, 20 and 30; higher porosities are available upon request. Custom-made cut-to-size filters are also possible.

-

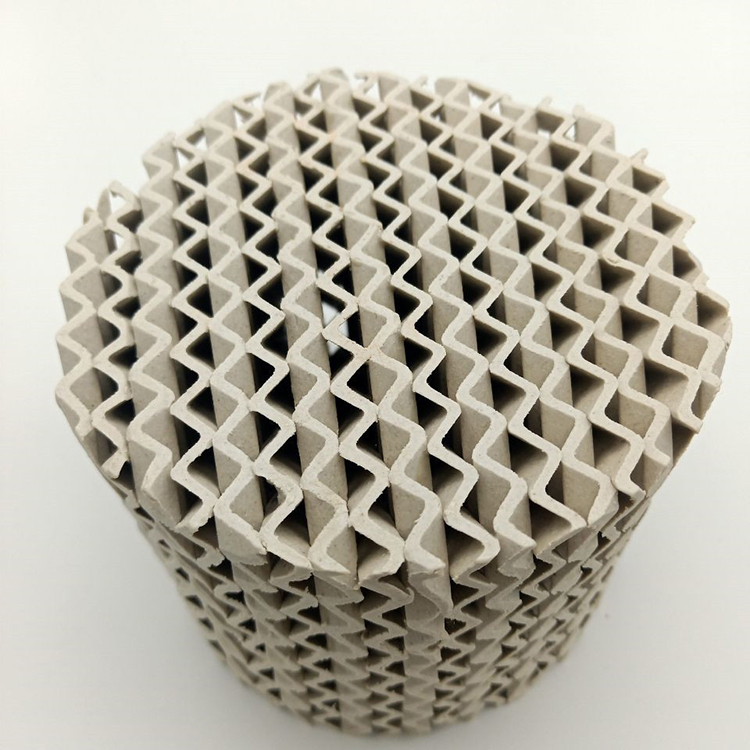

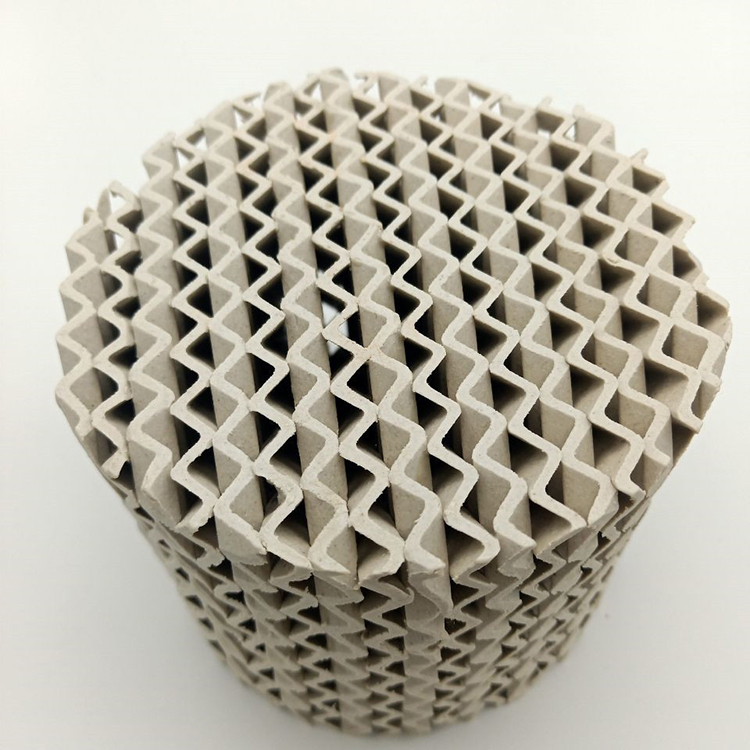

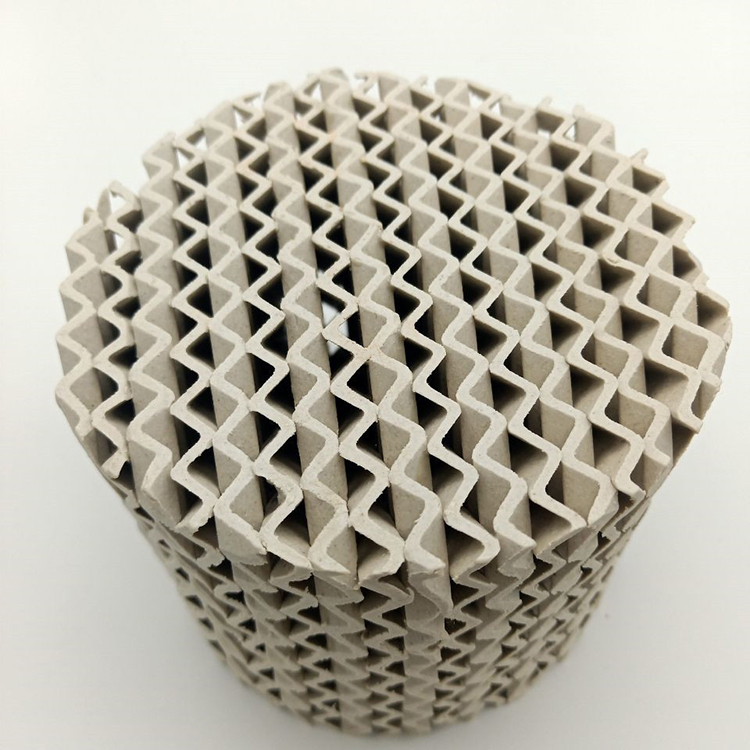

Hot-selling 125y 250y 350y Ceramic Structured Packing for Rectifying Tower

Ceramic Structured Packing consists of many packing units of similar geometric design. Corrugated sheets placed in parallel form cylindrical units called corrugated tower packing. These are a form of highly efficient packing with separating efficiency several times higher than that of loose packing. They have the quality of low-pressure drop, increased operating elasticity, minimum amplifying effect, and maximum liquid treatment compared to loose tower packing.

-

16mm 38mm 50mm 76mm SS304 SS316L Metal pall ring for Tower Packing

Metal Pall Ring is made of material like carbon steel, stainless steel or Alumina alloy, etc. The product has features such as thin wall, heat resistant, high free volume, high capacity, low resistance, high separation efficiency and so on. It is especially suitable for rectification towers under vacuum to treat thermo sensitive, decomposable, polymerizable or caokable systems, so it is widely used in packing towers in petrochemical industry , chemical fertilizer industry and environmental protection, etc.

Pall rings packing shows its interior and exterior surface contact which is beneficial to resist plugging, nesting, and fouling all along in with the distribution of liquid and gas. Pall rings function with versatility, high resistance to fouling, high temperature, and can be easily soaked.Metal pall ring is an industry standard design media developed from the raschig ring and is used widely in all-variety of applications. By minimizing the number of contours and crevices that can cause liquid hold-up and potential entrainment, the metal pall ring’s geometry enables high gas and liquid transfer rates.

-

Factory Outlets Cleaning Water Fiber Ball Polyester Filter Media Filter Ball in Swimming Pool

Fiber ball filter is spherical filter knotted by fiber,compared with traditional rigidity filter,has good elasticity,no floating, long working period and small head losses. In the filtering process, filter layer gap along the flow direction is becoming smaller, more accord with ideal filter material by big under small porosity distribution, thus forming the filter speed fast, cut pollution, large capacity, filtering effect is good, renewable repeatedly used and don’t change entirely and save Labour, etc.

-

Professional China PP Tri Pack Plastic Scrubber Bio Ball

Tri-Packs tower packing provides maximum surface contact between the gas and the scrubbing liquid by facilitating continuous formation of droplets throughout the packed bed. This results in high scrubbing efficiency, and minimizes total packing depth required.

-

Factory best selling 92% Al2O3 Ceramic Grinding Media Ball/Alumina Ceramic Beads for Wet Grinding

Alumina grinding ball has been widely used in ball mills as abrasive media for ceramic raw materals and glaze materials in ceramic factors, cement factories, enamel factories and glasswork owing to the extraordinarily high density, high hardness, high wear resistance. During the abrasive/grinding processes, ceramic aballs will not be broken, it will not comtaminate the materials to be grinded.

-

Supply 25mm 38mm 50mm 76mm Factory Price Ceramic Pall Ring Tower Packing

Ceramic pall ring is a type of classical random packing, which is developed from the Raschig ring. Commonly, there are two layers of windows opened along its cylinder wall. Each layer has five ligules bending inward the axes of the ring, which is similar to the metallic pall ring and plastic. But the layer and quantity of ligules may different according to the height and diameter variation.

Generally, the opening area occupies 30% of the total area of the cylinder wall. This design helps vapor and liquid flow freely through these windows, making full use of the inner surface of the ring to improve the distribution of vapor and liquid. It can also improve the separating efficiency.

Ceramic pall ring has excellent acid resistance and heat resistance. It can resist to corrosion of various inorganic acids,organic acids and organic solvents except hydrofluoric acid, and can be used in high or low temperature conditions.

Consequently the application range is very wide. It can be used in the drying columns, absorbing columns, cooling towers,scrubbing towers and actifier columns in chemical industry, metallurgy industry, coal gas industry, oxygen producing industry,etc. -

Professional China Polypropylene PP PE Rpp PVC CPVC PTFE PVDF Plastic Packing Pall Ring

Plastic Pall Ring packing is an economical and versatile industry standard with well-known performance characteristics. Plastic Pall ring has an advance on the Raschig Ring, the Pall Ring has similar cylindrical dimensions but has two rows of punched out holes, with fingers or webs turned into the centre of the cylinder, which significantly increases the performance of the packing, in terms of throughput, efficiency and pressure drop.

-

Reliable Supplier 50mm Copper Pall Ring SS304 SS316 Metal Pall Ring for Rectifying Tower

Metal Pall Ring is made of material like carbon steel, stainless steel or Alumina alloy, etc. The product has features such as thin wall, heat resistant, high free volume, high capacity, low resistance, high separation efficiency and so on. It is especially suitable for rectification towers under vacuum to treat thermo sensitive, decomposable, polymerizable or caokable systems, so it is widely used in packing towers in petrochemical industry , chemical fertilizer industry and environmental protection, etc.

Pall rings packing shows its interior and exterior surface contact which is beneficial to resist plugging, nesting, and fouling all along in with the distribution of liquid and gas. Pall rings function with versatility, high resistance to fouling, high temperature, and can be easily soaked.Metal pall ring is an industry standard design media developed from the raschig ring and is used widely in all-variety of applications. By minimizing the number of contours and crevices that can cause liquid hold-up and potential entrainment, the metal pall ring’s geometry enables high gas and liquid transfer rates.

-

Wholesale Price Mass Transfer Ceramic Random Packing Saddle Super Intalox Saddles for Heat Transfer Applications and Corrosive Environments

Ceramic intalox saddles has excellent acid resistance and heat resistance. It can resist to corrosion of various inorganic acids, organic acids and organic solvents except hydrofluoric acid, and can be used in high or low temperature conditions. Consequently the application range is very wide. It can be used in the drying columns, absorbing columns, cooling towers, scrubbing towers in chemical industry, metallurgy industry, coal gas industry, oxygen producing industry, etc. Ceramic intalox saddle is the opening packing with the structure of groove hemicycle, which reduce the cover between the packing and enlarge the space, therefore, the availability of the mass transfer surface will be enhanced efficiently, and it has favorable liquid distributing capability.

-

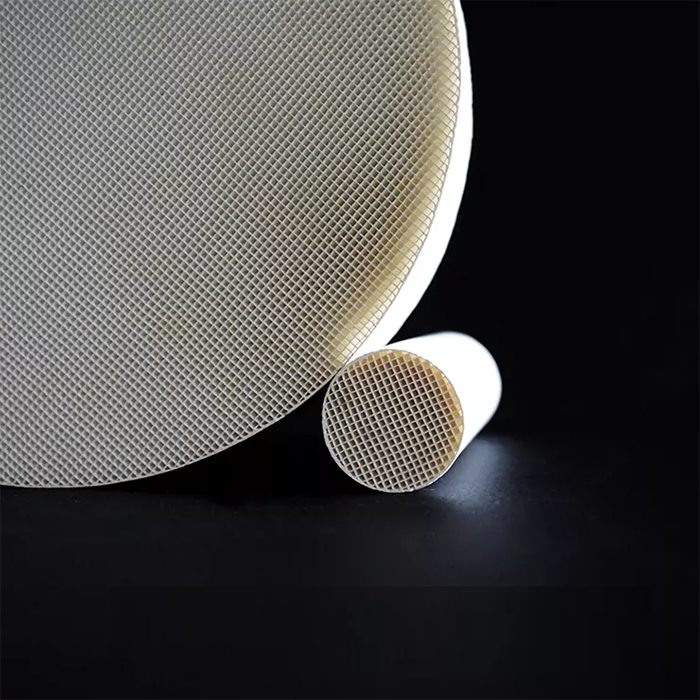

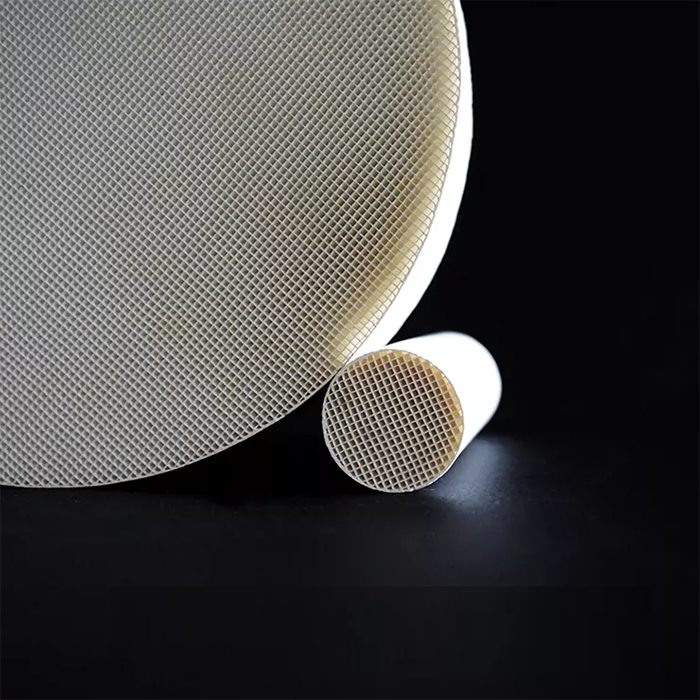

China Factory for China Catalyst Substrate Suppliers Doc Catalytic Converter Round Ceramic Honeycomb Catalytic Substrate Aftertreatment Diesel Oxidation Catalyst

The catalyst carrier is mainly used in the automotives and other high-temperature process exhaust. The main material is cordierite, after coated the catalyst, catalytic conversion of the exhaust, so as to achieve the national emission standards. It has characteristics of large surface area, small expansion coefficient, high strength, high water absorption, and good matching with the catalytic active component, heating up fast and so on.

-

BESTN Ceramic Structured Tower Packing for Distillation Column

Ceramic Structured Packing consists of many packing units of similar geometric design. Corrugated sheets placed in parallel form cylindrical units called corrugated tower packing. These are a form of highly efficient packing with separating efficiency several times higher than that of loose packing. They have the quality of low-pressure drop, increased operating elasticity, minimum amplifying effect, and maximum liquid treatment compared to loose tower packing.