-

-

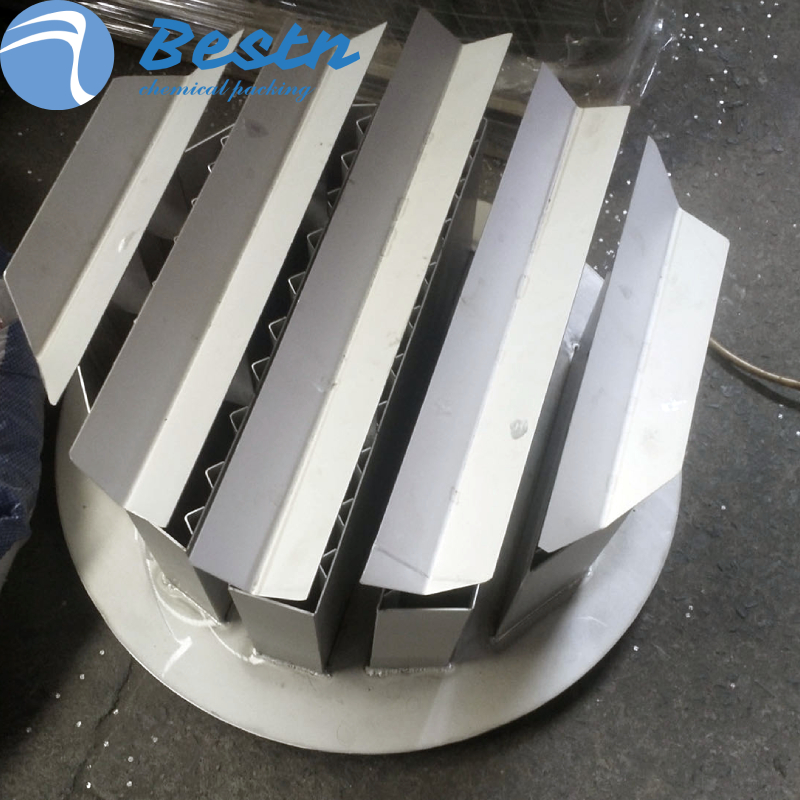

Metal Wire Gauze Structured Packing

1. Introduction:

Metal Wire Gauze Structured Packing Metal wire mesh structured packingis made up of silk screen tablets with bellows, and this bellows tablets have 30 or 45 inclination, adjacent bellows tablets is in opposite directions. When being filling in the tower, the filler from top to bottom is arrayed with staggered stacked.2.Application:

It is applied to vacuum distillation for difficult separation and thermal material, also it is applied to atmospheric distillation and absorption process, pressure operation, petrochemical, fertilizer, etc.- Technical Specification:

Model

Specific surface

Bulk density

Void ratio

Obl.

△P

Theo. plate

HETP/mm

F factor m/s (kg/m3)0.5

(m2/m3)

(kg/m3)

(%)

angle

(Pa/plate)

(piece/m)

250AX

250

125

95

30

100-400

2.5~3

100

2.5-3.5

500BX

500

250

90

30

400

4~5

200

2.0-2.4

700CY

700

350

85

45

600-700

8~10

333-400

1.5-2.0

packing picture

-

Factory Supply 16mm 25mm 38mm 50mm Metal Pall Ring

Item:Pall Ring

Materil:Stainless steel 304 316L

Size:16mm 25mm 38mm 50mm 76mm

Thickness:0.4-1.0mm as per your request

-

25mm 50mm SS304 316L 410 Metal Super Raschig Ring for Chemical Tower Packing

Raschig Super-Ring has a more than 30% greater load capacity, an almost 70% lower pressure drop and a mass transfer efficiency exceeding that of conventional metal packings by over 10%. The design of the Super Raschig Ring offers an optimal solution to industry’s demands for a modern heavy-duty packing.Raschig Super-Ring can be widely used in the packed tower of petrochemical, , fertilizer, environmental protection industries and so on. Especially suitable for vacuum distillation tower.

-

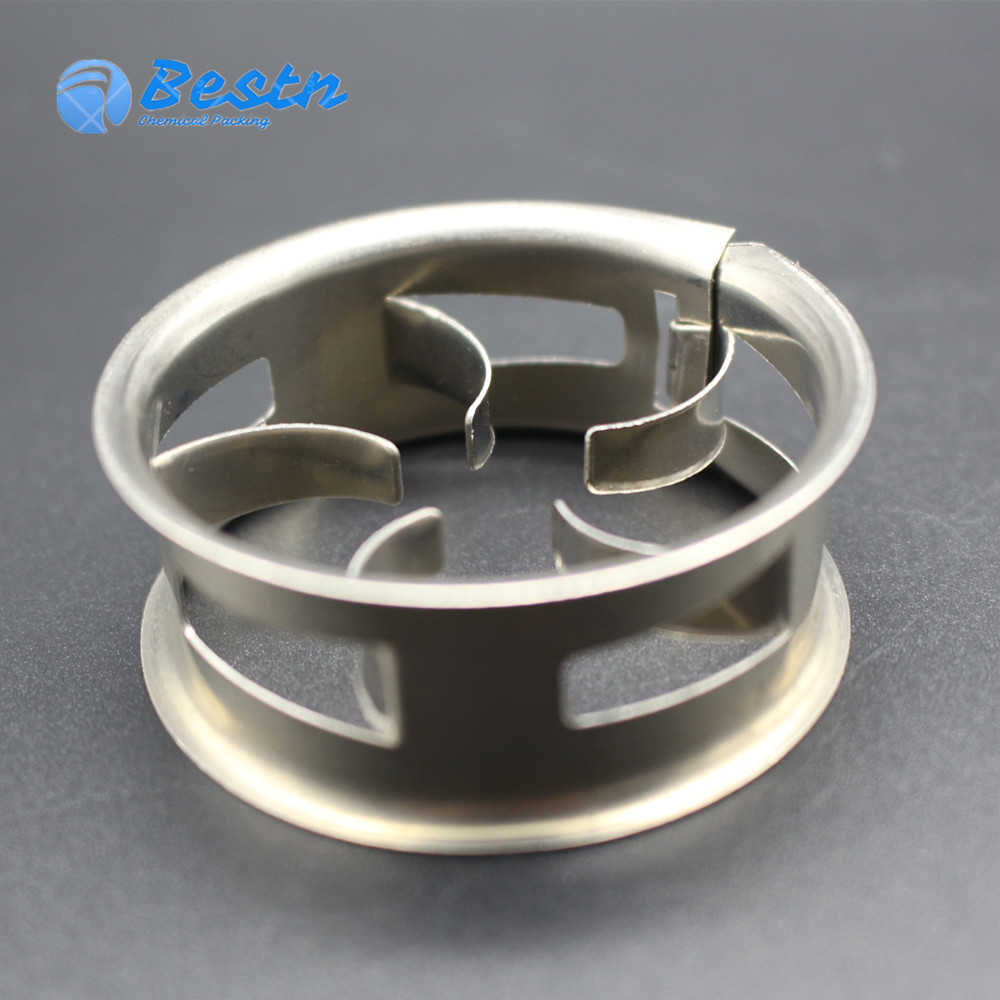

2″ 3″ Stainless Steel 304 316L 410 Super Raschig Ring for Metal Random Tower Packing

Raschig Super-Ring has a more than 30% greater load capacity, an almost 70% lower pressure drop and a mass transfer efficiency exceeding that of conventional metal packings by over 10%. The design of the Super Raschig Ring offers an optimal solution to industry’s demands for a modern heavy-duty packing.Raschig Super-Ring can be widely used in the packed tower of petrochemical, , fertilizer, environmental protection industries and so on. Especially suitable for vacuum distillation tower.

-

1″ 2″ 3″ Stainless Steel 304 316L Imtp Ring Metal Intalox Saddle Packing

Metal Intalox Saddle IMTP was developed by the United States Norton, between the shape of its saddle-shaped ring and between, and the advantages of both. Intalox metal structure in the saddle-shaped packing ring based on the increase of the annular tendon, to avoid overlap and ensure a certain degree of strength and rigidity out of a number of small claws, an increase of gas-liquid agitation, enhanced mass transfer, thus produce a unique performance.

Metal Intalox Saddle IMTP is referred to as domestic-shaped locks Intel fill, enjoy a high international reputation. This new type of efficient packing for the new equipment, packed tower, plate tower height lower than 35%, 30% decrease in diameter, or increase the efficiency of 10-30%, 20-60% reduction in pressure loss. Domestic wet instead of dry distillation distillation pilot study showed that 20 percent can reduce the investment. In short, the use of a new type of ring can be increased Intalox yield or low power costs and improve separation efficiency.

Metal Intalox Saddle can be a variety of materials, such as carbon steel, stainless steel 304, 304L, 410, 316, 316L, etc. to choose from.

-

304 316L Stainless Steel Vsp Ring Metal Inner Arc Ring For Tower Packing

Metallic VSP ring, also called inner arc ring, very special ring, is made of carbon steel, stainless steel, titanium alloy, aluminum alloy, copper alloy and stainless steel materials. Metallic VSP rings has reasonable geometric symmetry, which the inner arc are folded evenly along the axial direction and replaced alternated arranged. This design contributes a continuous surface for extremely high voidage and evenly distribution.

Metal VSP ring has the features of thin wall, large void ratio, high flowing, capacity, low pressure drop and good separation efficiency. So its application range is very wide, for drying, absorbing, cooling and regenerating tower in chemical metallurgic, coal gas and air separation industry.

-

SS304L 316L IMTP Ring Metal Intalox Ring for Chemical Tower Packing 25mm 40mm 50mm 76mm

Metal Intalox Saddle IMTP was developed by the United States Norton, between the shape of its saddle-shaped ring and between, and the advantages of both. Intalox metal structure in the saddle-shaped packing ring based on the increase of the annular tendon, to avoid overlap and ensure a certain degree of strength and rigidity out of a number of small claws, an increase of gas-liquid agitation, enhanced mass transfer, thus produce a unique performance.

Metal Intalox Saddle IMTP is referred to as domestic-shaped locks Intel fill, enjoy a high international reputation. This new type of efficient packing for the new equipment, packed tower, plate tower height lower than 35%, 30% decrease in diameter, or increase the efficiency of 10-30%, 20-60% reduction in pressure loss. Domestic wet instead of dry distillation distillation pilot study showed that 20 percent can reduce the investment. In short, the use of a new type of ring can be increased Intalox yield or low power costs and improve separation efficiency.

Metal Intalox Saddle can be a variety of materials, such as carbon steel, stainless steel 304, 304L, 410, 316, 316L, etc. to choose from.

-

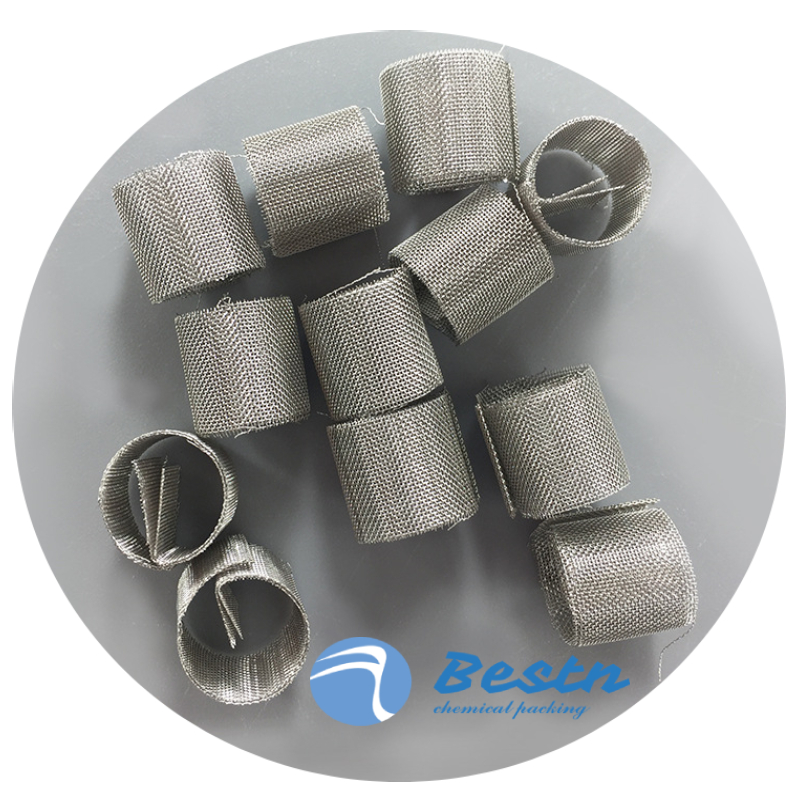

Stainless Steel Dixon Ring 2mm 3mm 4mm 5mm 6mm 7mm 8mm 9mm 10mm 12mm

The dixon ring packing is mainly used in the laboratory and the separation process of small batch, high purity products. The pressure drop of the dixon ring packing is related to the gas velocity, the amount of liquid spraying, the weight of the material system, the surface tension, the viscosity, and the characteristic factors of the packing, as well as the pre-flooding treatment of the packing.

-

Stainless Steel 304 316L Tower Internals Metal Trough Pan Type Gas-liquid Distributor for Packing Column

The trough pan liquid distributor is usually composed of a diversion groove (also known as the main groove or primary groove) and a distribution groove (also known as the secondary groove or secondary groove Slot).

-

SS304 304L 316L 316L Metal Cascade Mini Ring, Hooked CMR

Cascade mini ring is made of materials like carbon steel, stainless steel or Aluminum alloy, etc. The product has features such as thin wall, heat resistant, high free volume, high capacity, low resistance, high separation efficiency and so on. It is especially suitable for rectification towers under vacuum to treat thermosensitive, decomposable, polymerizable or cokable systems, so it is widely used in packing towers in petrochemical industry, chemical fertilizer industry and environmental protection, etc.

-

Random Packing Ss304 316L Metal Wire Mesh Dixon Ring Metallic Laboratory Column Packing Rings

The dixon ring packing is mainly used in the laboratory and the separation process of small batch, high purity products. The pressure drop of the dixon ring packing is related to the gas velocity, the amount of liquid spraying, the weight of the material system, the surface tension, the viscosity, and the characteristic factors of the packing, as well as the pre-flooding treatment of the packing.