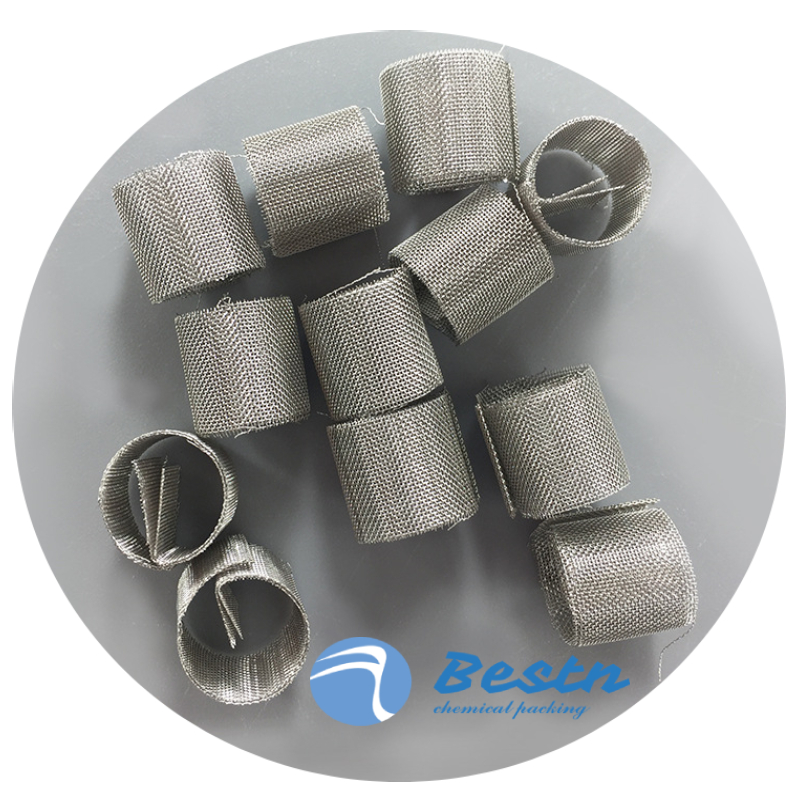

Random Packing Ss304 316L Metal Wire Mesh Dixon Ring Metallic Laboratory Column Packing Rings

Random Packing Ss304 316L Metal Wire Mesh Dixon Ring Metallic Laboratory Column Packing Rings

Dixon ring is a small particle high-efficiency filler, made of wire mesh, the diameter of the filler is equal to the height. The dixon ring packing is mainly used in the laboratory and the separation process of small batch, high purity products. The pressure drop of the dixon ring packing is related to the gas velocity, the amount of liquid spraying, the weight of the material system, the surface tension, the viscosity, and the characteristic factors of the packing, as well as the pre-flooding treatment of the packing. The stagnation amount of the Dixon ring packing is larger than that of the same kind of solid packing, the surface wetting of the dixon ring is also more complete than that of the general ceramic ring, and the film forming rate is higher, so the efficiency is also higher. The theoretical plate number of theta ring packing increases with the gas velocity and decreases with the decrease of the surface wettability of the packing.

|

Spec mm

|

Dia mm

|

Surface area m2/m3

|

Void space %

|

Bul density Kg/m3

|

Theoretical plate pcs/m

|

Pressure drop

|

|

mm(H2)/m

|

||||||

|

φ2×2

|

2*2*0.1

|

1500

|

93

|

570

|

22-23

|

23

|

|

φ3×3

|

3*3*0.1

|

1380

|

93

|

540

|

20-22

|

30

|

|

φ4×4

|

4*4*0.1

|

1340

|

93

|

480

|

14.5-15.5

|

147

|

|

φ5×5

|

5*5*0.1

|

1029

|

94

|

410

|

14-15

|

95

|

|

φ6×6

|

6*6*0.1

|

910

|

95

|

360

|

12-14

|

86

|

|

φ7×7

|

7*7*0.1

|

670

|

96

|

290

|

6-7

|

65

|

|

φ8×8

|

8*8*0.1

|

540

|

97

|

240

|

5-6

|

13

|

|

φ9×9

|

9*9*0.1

|

360

|

97.5

|

140

|

5

|

9

|

1. Dixon ring packing's pressure drop is related to gas velocity, liquid spray volume, and material weight, surface tension, viscosity and characteristics of fill factors and pre-fill liquid.

2. Dixon ring hysteresis loop filler material than similar entities fill large, its surface wetting situation completely than ordinary ceramic ring, film-forming rate, and thus more efficient.

3. Dixon ring packing with the theoretical plate number of the increase in gas velocity increased, with the filler surface wettability and reduce the rate of decline.

Dixon ring packing is mainly used in the laboratory and the separation process of small batch and high purity products, as well as the laboratory development of isotopes.This kind of packing plays an indispensable role in the process of distillation column, and corresponding specifications of packing are selected according to different tower diameters. Usually 1/8 or 1/10 of the tower diameter is selected Dixon A rough indicator of ring packing. The number of theoretical plates shall be determined by process calculation.