-

12″x12″x2″ Large Size Alumina Ceramic Foam Filter Plate for Filtration

Dimension (mm) Dimension (inch) Pouring rate (kg/s) Filtration capacity (ton) 178*178*50 7*7*2 0.2-0.6 5 228*228*50 9*9*2 0.3-1.0 10 305*305*50 12*12*2 0.8-2.5 15 381*381*50 15*15*2 2.2-4.5 25 430*430*50 17*17*2 3.0-5.5 35 508*508*50 20*20*2 4.0-6.5 45 585*585*50 23*23*2 5.0-8.6 60 Material Alumina Color White Pore Density 8-60ppi Porosity 80-90% Refractoriness ≤1200ºC Bending... -

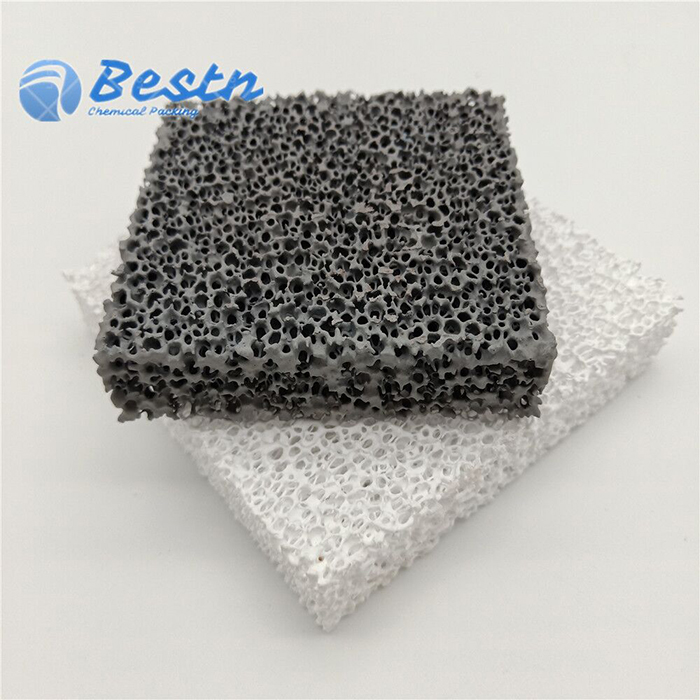

Refractory Silicon Carbide Sic Plate Ceramic Foam Filter for Iron Metal Casting

Silicon carbide foam ceramic filter using German imported polyurethane foam sponge as a carrier, silicon carbide mainly squeezed into the foam sponge, and then squeeze out the slurry,the slurry around the foam fiber, after drying, baking at high temperature,polyurethane thermal decomposition, leaving foam ceramic products, namely silicon carbide foam ceramic filter. The silicon carbide foam ceramic filter, with the three- dimensional mesh interconnection structure of foam sponge, can make met... -

-

Customize 10-60PPI Alumina Ceramic Foam Filter for Foundry

Dimension (mm) Dimension (inch) Pouring rate (kg/s) Filtration capacity (ton) 178*178*50 7*7*2 0.2-0.6 5 228*228*50 9*9*2 0.3-1.0 10 305*305*50 12*12*2 0.8-2.5 15 381*381*50 15*15*2 2.2-4.5 25 430*430*50 17*17*2 3.0-5.5 35 508*508*50 20*20*2 4.0-6.5 45 585*585*50 23*23*2 5.0-8.6 60 Material Alumina Color White Pore Density 8-60ppi Porosity 80-90% Refractoriness ≤1200ºC Be... -

Customize 8-60PPI SIC/Silicon Carbide Ceramic Foam Filter for Gas filtration and Purification

SiC Ceramic Foam Filters common sizes in Round shape: 40x11mm, 40x15mm, 50x15mm, 50x20mm, 60x22mm, 70x22mm, 80x22mm , 90x22mm,100x22mm, 305x25mm SiC Ceramic Foam Filters common sizes in Square shape: 40x40x11mm, 40x40x15mm, 50x50x22mm, 75x75x22mm, 50x75x22mm, 100x75x22mm, 100x100x22mm, 55x55x15mm, 150x150x22mm ● Decontaminate the melting metal liquid ● Simplified gating system ● Improve the metallurgical structure of the castings ● Reduce imparities of the castings ● Improve... -

10-30PPI Zirconia Ceramic Foam Filter for Casting

Zirconia foam ceramic filter is made of high-quality and high-purity zirconia, using unique formula and advanced environmental protection technology. It has a uniform three-dimensional network structure, high strength, stable texture, no slag dropping, high temperature resistance, and thermal shock resistance ect excellent performance. Suitable for purification and filtration of stainless steel, carbon steel, copper castings and other high temperature alloy solutions below 1700C. Can filter non-metal slag inclusions and slags as small as micrometers, making the surface of steel castings smoother and reducing machining losses; the filter can make the molten steel fill the cavity more uniformly, and the molten metal has a higher turbulence during pouring tendency, the turbulent flowing through the three-dimensional pore structure is finally converted into a very stable laminar flow. Laminar flow fills the cavity better, which reduces the impact corrosion of the metal solution on the casting cavity, and significantly reduces the reject rate, reduces production costs, and improves labor productivity.

-

Zirconia Ceramic Foam Filter for Magnesium Oxide Casting Resistance 1700º C Filter Mesh for Casting

Zirconia foam ceramic filter is made of high-quality and high-purity zirconia, using unique formula and advanced environmental protection technology. It has a uniform three-dimensional network structure, high strength, stable texture, no slag dropping, high temperature resistance, and thermal shock resistance ect excellent performance. Suitable for purification and filtration of stainless steel, carbon steel, copper castings and other high temperature alloy solutions below 1700C. Can filter non-metal slag inclusions and slags as small as micrometers, making the surface of steel castings smoother and reducing machining losses; the filter can make the molten steel fill the cavity more uniformly, and the molten metal has a higher turbulence during pouring tendency, the turbulent flowing through the three-dimensional pore structure is finally converted into a very stable laminar flow. Laminar flow fills the cavity better, which reduces the impact corrosion of the metal solution on the casting cavity, and significantly reduces the reject rate, reduces production costs, and improves labor productivity.

-

SIC/Silicon carbide Ceramic Foam Filter for non-ferro alloy molten metal filtration

Silicon Carbide Ceramic Foam Filters mainly for filtration of cast iron and non-ferrous alloys. With their excellent resistance to attack and corrosion from molten iron liquid, they can effectively remove inclusions, reduce trapped gas from liquid metal and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit. SiC Ceramic Foam Filters is available in all standard dimensions and different thickness. The most common porosities are PPI 10, 20 and 30; higher porosities are available upon request. Custom-made cut-to-size filters are also possible.

-

Alumina Ceramic Foam Filter for Molten aluminium alloy filtration

Alumina Foam ceramics foundry filter are mainly used for filtration of aluminium and aluminium alloys in foundries and cast houses . With their excellent thermal shock resistance and corrosion resistance from molten aluminum, they can effectively eliminate inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

-

zirconia casting ceramic foam filter

Zirconia foam ceramic filter is made of high-quality and high-purity zirconia, using unique formula and advanced environmental protection technology. It has a uniform three-dimensional network structure, high strength, stable texture, no slag dropping, high temperature resistance, and thermal shock resistance ect excellent performance. Suitable for purification and filtration of stainless steel, carbon steel, copper castings and other high temperature alloy solutions below 1700C. Can filter non-metal slag inclusions and slags as small as micrometers, making the surface of steel castings smoother and reducing machining losses; the filter can make the molten steel fill the cavity more uniformly, and the molten metal has a higher turbulence during pouring tendency, the turbulent flowing through the three-dimensional pore structure is finally converted into a very stable laminar flow. Laminar flow fills the cavity better, which reduces the impact corrosion of the metal solution on the casting cavity, and significantly reduces the reject rate, reduces production costs, and improves labor productivity.