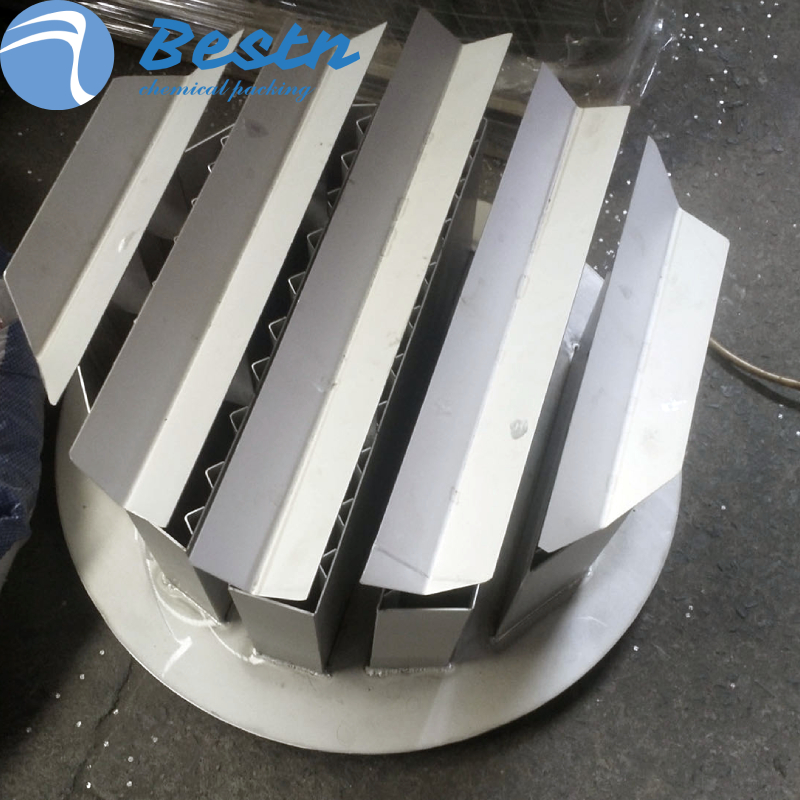

Stainless Steel 304 316L Tower Internals Metal Trough Pan Type Gas-liquid Distributor for Packing Column

Stainless Steel 304 316L Tower Internals Metal Trough Pan Type Gas-liquid Distributor for Packing Column

|

Liquid Distributor Comparison

|

|||||||

|

Item

|

Ladder type

|

Spray nozzle type

|

Pan with bottom hole

|

Trough with bottom hole

|

Pan with flow

|

Trough with overflow

|

|

|

Power

|

pressure

|

gravity

|

pressure

|

gravity

|

gravity

|

gravity

|

gravity

|

|

Distribution quality

|

Middle

|

High

|

Low to middle

|

High

|

High

|

Low to middle

|

Low to middle

|

|

capacity

m3/(m2·h)

|

0.25-2.5

|

0.25-10

|

Wide range

|

Wide range

|

Wide range

|

Wide range

|

Wide range

|

|

Tower dia. /m

|

>0.45

|

Any

|

Any

|

Any, often<1.2

|

Any, often>0.6

|

Any, often<1.2

|

Any, often>0.6

|

|

Plugging degree

|

High

|

High

|

Middle to high

|

Middle

|

Middle

|

Low

|

Low

|

|

Air resistance

|

Low

|

Low

|

Low

|

High

|

Low

|

High

|

Low to high

|

|

Levelness requirements

|

None

|

Low

|

None

|

High at low load

|

High at low load

|

High

|

high

|

|

Effect of corrosion

|

High

|

Middle

|

High

|

High

|

High

|

Low

|

Low

|

|

Influence of liquid level fluctuation

|

None

|

Small

|

None

|

Middle

|

Middle

|

Big

|

Big

|

|

Entrainment

|

High

|

Low

|

High

|

Low

|

Low

|

Low

|

Low

|

|

Weight

|

Low

|

Low

|

Low

|

High

|

Middle

|

High

|

middle

|

|

Column Diameter

mm

|

Specific liquid load

M3/m2*h

|

System fouling tendency

|

Turndown ratio

|

Suitable type of liquid distributor

|

|

250 - 900

|

0.75 - 5

|

Low - medium

|

<10:1

|

Trough type liquid distributor with sump

Deck type liquid distributor with orifices on drip tubes

|

|

5 - 30

|

Low - medium

|

2:1

|

Pan type liquid distributor

Trough type liquid distributor with sump

|

|

|

>30

|

Low - medium

|

2:1

|

Pan type liquid distributor

Trough type liquid distributor with sump

Deck type liquid distributor

|

|

|

>900

|

0.75 - 5

|

Low - medium

|

<10:1

|

Trough type liquid distributor with parting box

Deck type liquid distributor with orifices on drip tubes

|

|

5 - 30

|

Low - medium

|

2:1

|

Trough type liquid distributor with sump

Trough type liquid distributor with parting box

Deck type liquid distributor

|

|

|

>30

|

Low - medium

|

2:1

|

Deck type liquid distributor

Trough type liquid distributor with sump

|

Metal: Stainless steel 304, 304L, 316, 316L, 410, Carbon steel, other materials on request.

1. Superior liquid distribution performance, suitable for situations with more spray points and lower liquid loads.

2. It is required that there are no solid particles in the material, and a filter screen should be installed at the inlet of the riser.

3. The tubular liquid distributor has good operational flexibility.

4. In situations with high operational flexibility, a double row tube liquid distributor can be used.

5. Suitable for use in large, medium, and small towers.

The difference and working principle between trough type distributor and trough pan type distributor:

1. The principle of liquid distribution is the same, but the gas channels are different.

2. Both liquid distributions utilize the principle of consistent liquid velocity at the same liquid level

3. The gas in the slot distributor passes through the slots, and the slot plate distribution has an riser as the gas channel

4. The slot distributor and the tower are point supports, while the operating tray distributor needs to be welded to the tower.

5. The trough type should be more reliable, as improper installation of the trough pan type may cause leakage.

6. The trough type liquid distributor is a liquid distributor with excellent comprehensive performance. The trough type liquid distributor has the advantages of easy installation, uniform liquid distribution, high spray point density, and extremely low pressure drop, and is currently widely used.

7. Trough type gas-liquid distributor The trough type gas-liquid distributor combines the functions of a liquid collector, a liquid distributor, a gas distributor, and all three. It has the advantages of low occupied space height, strong anti clogging ability, no liquid droplet entrainment, high operating flexibility, and reduced pressure.

1.Tower internals

Used as an internal component in chemical equipment such as desulfurization towers, distillation towers, and absorption towers for mist or dust separation, achieving air purification, flue gas desulfurization, and water purification treatment purposes.

2.Chemical industry

3.Petroleum

4.Others