Factory best selling 92% Al2O3 Ceramic Grinding Media Ball/Alumina Ceramic Beads for Wet Grinding

Factory best selling 92% Al2O3 Ceramic Grinding Media Ball/Alumina Ceramic Beads for Wet Grinding

It really is a good way to further improve our goods and service. Our mission would be to acquire inventive items to buyers with a very good encounter for Factory best selling 92% Al2O3 Ceramic Grinding Media Ball/Alumina Ceramic Beads for Wet Grinding, The main purpose of our company is always to live a satisfactory memory to many of the customers, and establish a lengthy time period enterprise romantic relationship with prospective buyers and users all over the environment.

It really is a good way to further improve our goods and service. Our mission would be to acquire inventive items to buyers with a very good encounter for China Alumina Ball Price and Grinding Ball, Our company always concentrate on the development of the international market. We have now a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

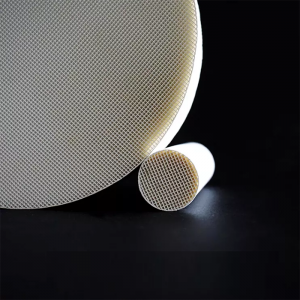

1) Grinding ceramic ball is one ideal ball mill grinding media, it can keep the purity and improve the stability of grinded materials.

2) The alumina grinding ball have been widely used in ball mills as abrasive media for ceramic raw materials and glaze materials in ceramic factories, cement factories, enamel factories and glasswork.

3) The main features are high density, high hardness and strength, high wear resistance, thermal stability, corrosion resistance and non-pollution etc.

4) During the abrasive/grinding processes, ceramic balls will not be broken, it will not contaminate the materials to be grinded.

5) Type: According to the content of aluminum oxide: 60-70%, 65-75%, 95%.

|

Specification |

65Alumina Ball |

75Alumina Ball |

90Alumina Ball |

92Alumina Ball |

95Alumina Ball |

99Alumina Ball |

|

Al2O3(%) |

≥65 |

≥75 |

≥90 |

≥92 |

≥95 |

≥99 |

|

Fe2O3(%) |

≤0.5 |

≤0.5 |

≤0.1 |

≤0.1 |

≤0.1 |

≤0.1 |

|

Moh’s Hardness |

8 |

8~9 |

9 |

9 |

9 |

9 |

|

Water Adsorption (%) |

≤0.05 |

≤0.05 |

≤0.02 |

≤0.02 |

≤0.02 |

≤0.01 |

|

Density (g/cm3) |

≥2.95 |

≥3.25 |

≥3.55 |

≥3.60 |

≥3.65 |

≥3.8 |

|

Crush Strength (MPa) |

≥1650 |

≥1700 |

≥1900 |

≥2000 |

≥2250 |

≥2500 |

|

Abrasion Loss (%) |

≤0.03 |

≤0.02 |

≤0.01 |

≤0.01 |

≤0.01 |

≤0.01 |

|

High Alumina Grinding Balls |

Medium Alumina Grinding Balls |

Carbonized Alumina Grinding Balls |

|

|

Color |

White |

White |

Ash-black |

|

Crack |

Not Permission |

Not Permission |

Not Permission |

|

Impurity |

Not Permission |

Not Permission |

Not Permission |

|

Foam hole |

Above ф1mm not permission, size in ф0.5mm permit 3 balls |

||

|

Flaw |

Max. size in ф0.3mm permit 3 balls |

||

It really is a good way to further improve our goods and service. Our mission would be to acquire inventive items to buyers with a very good encounter for Factory best selling 92% Al2O3 Ceramic Grinding Media Ball/Alumina Ceramic Beads for Wet Grinding, The main purpose of our company is always to live a satisfactory memory to many of the customers, and establish a lengthy time period enterprise romantic relationship with prospective buyers and users all over the environment.

Factory best selling China Alumina Ball Price and Grinding Ball, Our company always concentrate on the development of the international market. We have now a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.