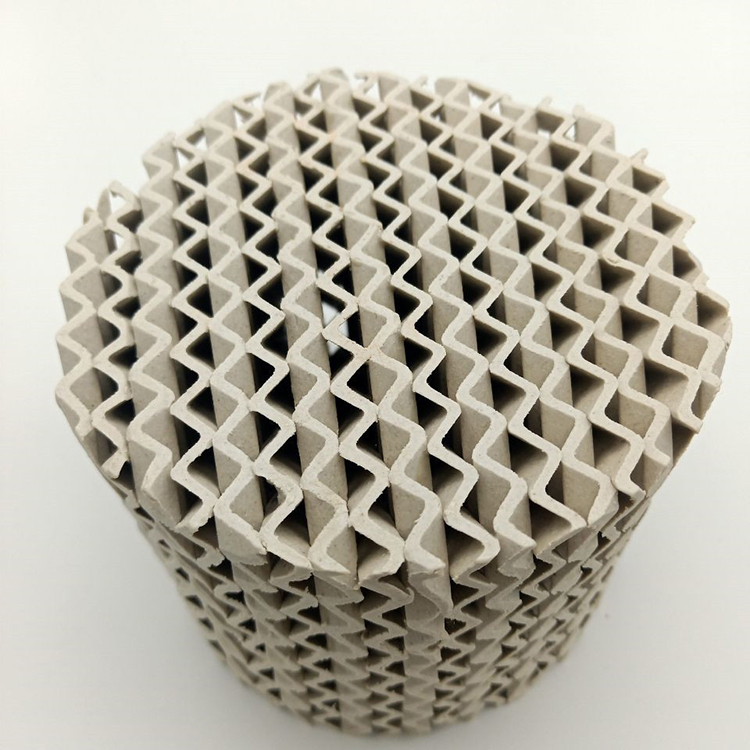

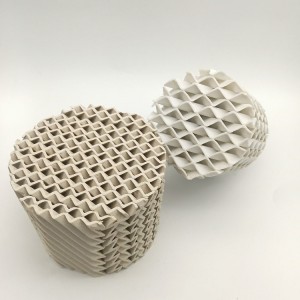

BESTN Ceramic Structured Tower Packing for Distillation Column

BESTN Ceramic Structured Tower Packing for Distillation Column

With superior technologies and facilities, strict quality command, reasonable cost, exceptional provider and close co-operation with customers, we’ve been devoted to delivering the best benefit for our buyers for BESTN Ceramic Structured Tower Packing for Distillation Column, We always hold the philosophy of win-win, and build long-term cooperation relationship with customers from around the world.We believe that our growth base on customer’s success, credit is our life.

With superior technologies and facilities, strict quality command, reasonable cost, exceptional provider and close co-operation with customers, we’ve been devoted to delivering the best benefit for our buyers for China Ceramic Structured Tower Packing and Ceramic Structured Packings, Custom orders are acceptable with different quality grade and customer’s especial design. We’re looking forward to establish the good and successful cooperation in business with long terms from the customers of all over the world.

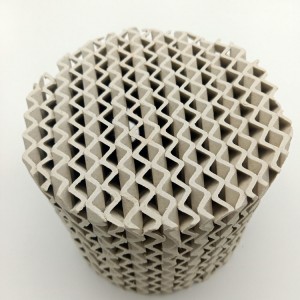

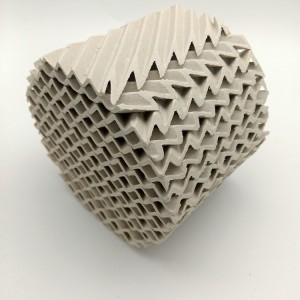

Ceramic Structured Packing consists of many packing units of similar geometric design. Corrugated sheets placed in parallel form cylindrical units called corrugated tower packing. These are a form of highly efficient packing with separating efficiency several times higher than that of loose packing. They have the quality of low-pressure drop, increased operating elasticity, minimum amplifying effect, and maximum liquid treatment compared to loose tower packing.

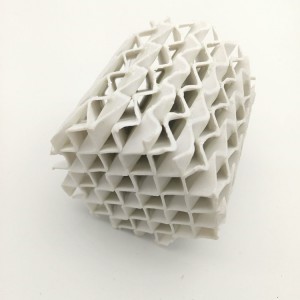

|

Composition |

Value |

|

SiO2 |

≥72% |

|

Fe2O3 |

≤0.5% |

|

CaO |

≤1.0% |

|

Al2O3 |

≥23% |

|

MgO |

≤1.0% |

|

Other |

2% |

● High capacity. New tower design may reduce diameter, while renovate old towers may increase capacity significantly.

● High separation efficiency. Since it has much larger specific surface area compared to random packing.

● Low pressure drop, which leads to reduce energy consumption largely.

● Large flexibility, and scale effect is not obvious.

● Suitable for all tower diameters.

● Strong resistance to corrosion of acid and alkali, especially to H2S, naphthenic acid and Cl-.

● Rectifying organic halide.

● Rectifying and absorbing some corrosive mixtures, which are definitely regulated in pressure drop and theoretic plate number.

● Applied in some towers that contain a large quantity of natural media used to absorb nitric acid and concentrated sulfuric acid, as well as for purifying the air in chemical plants.

● Operating in vacuum conditions at a bottom absolute pressure of 100pa.

● Used in heat ex changer and demisting, or as a catalyst carrier.

1. High liquid & vapor loading, Column diameter could be designed smaller for new equipment and capacity could be increased

dramatically for existing column revamp.

2. High resistance to nearly all mineral and organic acids and derivatives, partly resistant to alkali.

3. High mass-transfer efficiency. Much higher specific surface area than random packing.

4. Low pressure drop, considerable energy savings.

5. Wide turn down ratio. Easy to scale up.

6. Suitable for all sizes of column.

With superior technologies and facilities, strict quality command, reasonable cost, exceptional provider and close co-operation with customers, we’ve been devoted to delivering the best benefit for our buyers for Bestn Ceramic Structured Tower Packing for Distillation Column, We always hold the philosophy of win-win, and build long-term cooperation relationship with customers from around the world.We believe that our growth base on customer’s success, credit is our life.

2019 China New Design China Ceramic Structured Tower Packing and Ceramic Structured Packings, Custom orders are acceptable with different quality grade and customer’s especial design. We’re looking forward to establish the good and successful cooperation in business with long terms from the customers of all over the world.