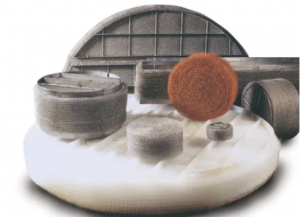

Plastic PP Mist Eliminator Demister Mesh for Gas Liquid Separation

Plastic PP Mist Eliminator Demister Mesh for Gas Liquid Separation

Demister pad, also called mist pad, wire mesh demister, mesh mist eliminator, catching mist, mist eliminator. Demister Pads are woven with multi layer knitted mesh in different densities. It is used in gas entrained mist separation column to guarantee the filtering efficiency.

wire, the drops will become bigger and bigger. They will be separated and fall when their own weight exceed the resultant force of buoyancy of the rising gas and surface tension of liquid. They will flow to the device of the container in the backward position.As long as the speed of the gas is properly controlled and with other proper condition, the efficiency of foam remove will be as high as 97% after the gas pass through wire-mesh demister. The purpose of removing foam will be achieved completely.

* Lightweight. The density of PP demister pad is 0.90 - 0.91 g/cm3, it is one of the lightest material in the plastics.

* High temperature resistance. the PP demister pad can maintain good condition in max. 150 °C.

* Chemical stability. The PP demister pad has outstanding corrosion, acid, alkali and various chemical agent.

* Low pressure drop.

* Good mechanical property.

* Good strength and hardness.

* Excellent elasticity.

* High filtering and separating efficiency.

* Convenient for installing and uninstalling.

* Simple structure.

PP demister pad has outstanding separating efficiency, which can filter out the tiny liquid foam, so it is widely used in the

environmental protection applications for flue gas desulfurization.

The PP demister pad is widely used in the production process to purify the air and protect the environment through filtering out the water, mist, dust and harmful substances.

Polypropylene, Glass Filled Polypropylene, Low Density Polyethylene, High Density Polyethylene, PVC, CPVC, Kynar (PVDF), Halar (E-CTFE), Tefzel (ETFE), Glass Filled ETFE, PFA.

1. High mass transfer efficiency.

2. Low pressure drop.

3. High flux.

4. High gas velocity.

|

Package |

Plastic bag |

Super sack |

Carton |

|

1X20GP |

25m3 |

20-24m3 |

20m3 |

|

1X40GP |

54m3 |

40m3 |

40m3 |

![{TZY]OIS2Q~P6R5{]1~9IZ5](https://i974.goodao.nethttps://cdn.globalso.com/bestnpacking/TZYOIS2QP6R519IZ5.png)