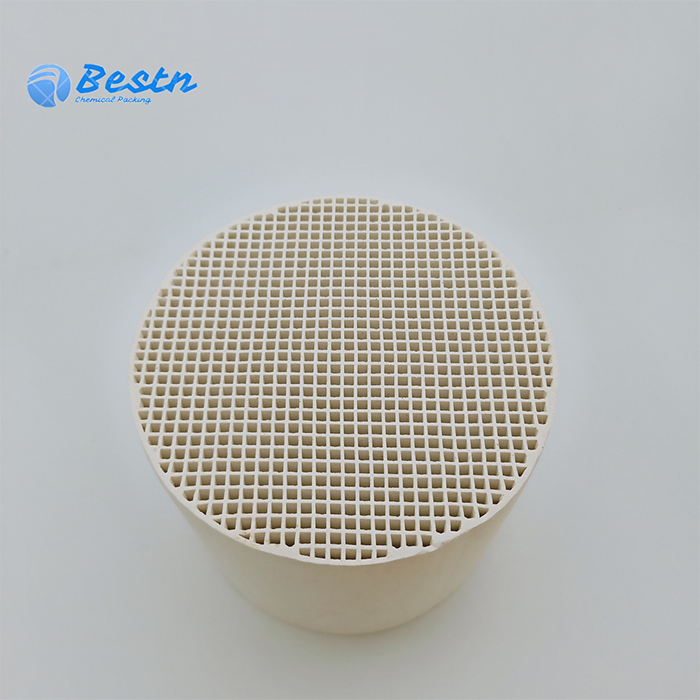

Thermal Storage RTO RCO Ceramic Honeycomb For Heat Recovery

Thermal Storage RTO RCO Ceramic Honeycomb For Heat Recovery

● Reduce the thermal loss of exhaust gas, and improve the efficiency

● Enhance the theory burning temperature, improve the atmospheric burning, meet the high temperature of thermal equipment, enlarge the application of low calorific value, especially the application range of blast furnaces, improve the efficiency of calorific value and reduce the emissions from low calorific value coal gas.

● Improve the terms of heat exchange in hearths, increase the output of equipment, enhance the quality of products and cut down on reinvesting in equipment/

● Reduce the exhaust emission of thermal equipment, alleviate the air pollution and improve the environment.

● High temperature resistance, corrosion resistance, good thermal shock resistance, high strength, large heat storage capacity, good thermal conductivity, etc. and the energy saving effect and the service life are greatly improved.

● Widely used in all kinds of heating furnace, hot blast furnace, heat treatment furnace, cracking furnace, baking equipment, melting furnace, soaking furnace, oil and gas boiler furnace in iron and steel industry, building materials industry, chemical industry, petrochemical industry, paint industry, non-ferrous metal smelting industry.

|

Properties of Honeycomb Ceramics |

|||||

|

Item |

Unit |

Alumina Ceramic |

Dense Cordierite |

Cordierite |

Mullite |

|

Density |

g/cm3 |

2.68 |

2.42 |

2.16 |

2.31 |

|

Bulk Density |

kg/m3 |

965 |

871 |

778 |

832 |

|

Thermal Expansion Coefficient |

10-6/k |

6.2 |

3.5 |

3.4 |

6.2 |

|

Specific Heat Capacity |

j/kg·k |

992 |

942 |

1016 |

998 |

|

Thermal Conductivity |

w/m·k |

2.79 |

1.89 |

1.63 |

2.42 |

|

Thermal Shock Resistance |

Max K |

500 |

500 |

600 |

550 |

|

Softening Temperature |

℃ |

1500 |

1320 |

1400 |

1580 |

|

Maximum Service Temperature |

℃ |

1400 |

1200 |

1300 |

1480 |

|

Average Heat Capacity |

w/m·k/m3·k |

0.266 |

0.228 |

0.219 |

0.231 |

|

water Absorption |

% |

≤20 |

≤5 |

15-20 |

15-20 |

|

Acid Resistance |

% |

0.2 |

5.0 |

16.7 |

2.5 |

|

Parameters of Honeycomb Ceramics |

|||||||

|

Overall dimension |

Cell pattern |

Cell Number |

Cell Width |

Inner Wall |

Outer Wall |

Specific Surface Area m2/m3 |

Void Fraction |

|

150*150*300 |

Square |

5*5=25 |

26 |

3.05 |

3.5 |

146 |

76% |

|

150*150*300 |

Square |

13*13=169 |

9.3 |

2.05 |

2.5 |

310 |

65% |

|

150*150*300 |

Square |

25*25=625 |

5 |

0.95 |

1.5 |

582 |

69% |

|

150*150*300 |

Square |

32*32=1024 |

3.9 |

0.8 |

1.3 |

736 |

67% |

|

150*150*300 |

Square |

40*40=1600 |

3 |

0.67 |

1.3 |

892 |

66% |

|

150*150*300 |

Square |

43*43=1849 |

2.8 |

0.65 |

1.3 |

964 |

64% |

|

150*150*300 |

Square |

50*50=2500 |

2.4 |

0.6 |

1.1 |

1104 |

62% |

|

150*150*300 |

Square |

60*60=3600 |

2 |

0.5 |

1.1 |

1291 |

62% |

|

200*100*100 |

Circle |

20*9=180 |

8.5 |

2.3 |

2.5 |

280 |

51% |

|

150*100*100 |

Square |

36*24=864 |

3 |

1.1 |

1.2 |

734 |

52% |

|

150*100*100 |

Hexagon |

35*20=700 |

4 |

1 |

1.2 |

687 |

65% |

|

150*100*100 |

Hexagon |

10*6=60 |

12 |

4 |

4 |

210 |

50% |

|

150*100*100 |

Hexagon |

35*20=700 |

3.5 |

1.5 |

1.5 |

570 |

50% |

|

150*100*100 |

Circle |

17*13=221 |

7.5 |

1.2 |

1.3 |

366 |

57% |

|

150*100*100 |

Circle |

33*19=627 |

4 |

1 |

1.3 |

568 |

53% |

|

150*100*100 |

Circle |

15*9=135 |

8.5 |

2.3 |

2.5 |

280 |

51% |

|

150*100*100 |

Hexagon |

38*22 =836 |

3.6 |

0.9 |

1.2 |

696 |

63% |

|

150*100*100 |

Square |

42*28=1176 |

2.6 |

1 |

1.1 |

815 |

53% |

|

100*100*100 |

Hexagon |

7*6=42 |

12 |

4 |

4 |

224 |

52% |

|

100*100*100 |

Square |

31*31=961 |

2.65 |

0.55 |

0.7 |

1065 |

67% |

|

100*100*100 |

Square |

24*24=576 |

3 |

1.1 |

1.2 |

741 |

52% |

|

100*100*100 |

Hexagon |

23*20=460 |

4 |

1 |

1.2 |

608 |

64% |

|

100*100*100 |

Circle |

10*9=90 |

8.5 |

2.3 |

2.5 |

280 |

51% |