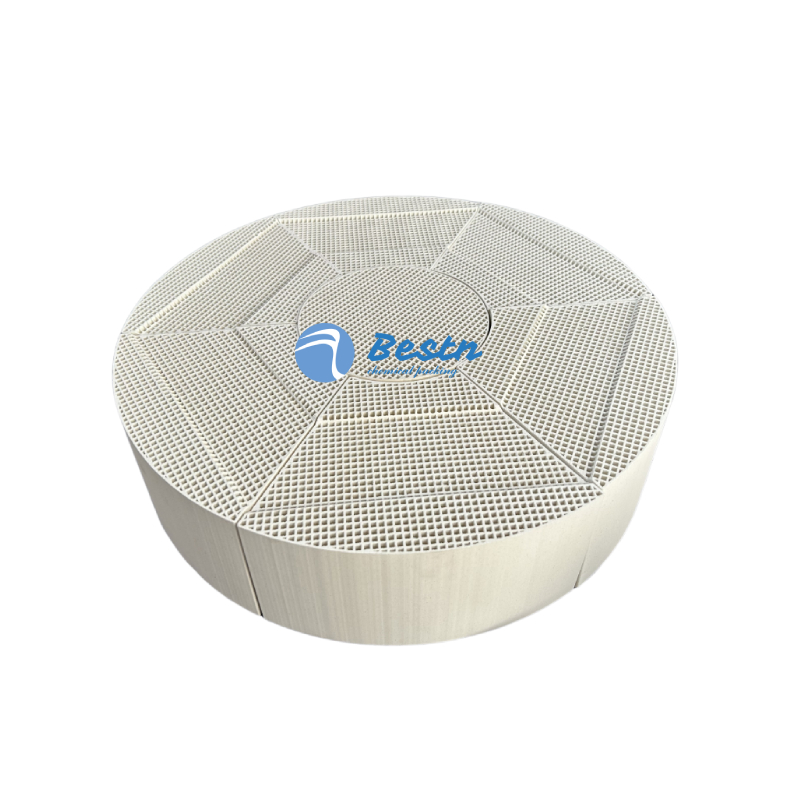

Cordierite Cylindrical Fan-shaped Honeycomb Ceramic Regenerator for Ladle and Intermediate Ladle Baking Device

Cordierite Cylindrical Fan-shaped Honeycomb Ceramic Regenerator for Ladle and Intermediate Ladle Baking Device

Honeycomb ceramic regeneration have significant advantages such as high temperature resistance, corrosion resistance, good thermal shock stability, high strength, large heat storage capacity, and good thermal conductivity, greatly increasing their effectiveness and service life.

|

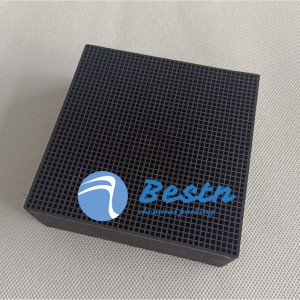

Square hole honeycomb ceramics

|

||||

|

Size(mm)

|

Hole diameter(mm)

|

Wall Thickness(mm)

|

Heat transfer area(m2/m3)

|

Opening ratio(%)

|

|

150*100*100

|

¢2.5

|

1

|

784

|

49

|

|

150*100*100

|

¢3.0

|

1.1

|

691

|

52

|

|

150*100*100

|

¢5.0

|

2

|

392

|

49

|

|

100*100*100

|

¢2.5

|

1

|

784

|

49

|

|

100*100*100

|

¢3.0

|

1.1

|

691

|

52

|

|

100*100*100

|

¢5.0

|

2

|

392

|

49

|

|

165*110*100

|

¢3.0

|

1.1

|

670

|

52

|

|

Hexagonal hole honeycomb ceramics

|

||||

|

Size(mm)

|

Hole diameter (mm)

|

Wall Thickness(mm)

|

Heat transfer area(m2/m3)

|

Opening ratio(%)

|

|

150*100*100

|

3.1

|

1

|

673

|

53

|

|

150*100*100

|

3.1

|

1.5

|

625

|

49

|

|

150*100*100

|

3.5

|

1

|

655

|

58

|

|

150*100*100

|

3.9

|

1.1

|

624

|

58

|

|

100*100*100

|

3.1

|

1

|

673

|

53

|

|

100*100*100

|

3.5

|

1

|

655

|

58

|

|

100*100*100

|

3.9

|

1.1

|

624

|

58

|

|

Fan-shaped honeycomb ceramics

|

|||||

|

Size(mm)

|

Inner hole size(mm)

|

Hole diameter(mm)

|

Wall Thickness(mm)

|

Heat transfer area(m2/m3)

|

Opening ratio(%)

|

|

¢630

|

¢200

|

¢3.0

|

1

|

691

|

52

|

|

¢540

|

¢200

|

¢3.0

|

1

|

691

|

52

|

|

¢420

|

¢154

|

¢3.0

|

1

|

691

|

49

|

|

¢152

|

¢36

|

¢3.0

|

1

|

691

|

49

|

|

Circular hole honeycomb ceramic

|

||||

|

Size(mm)

|

Hole diameter(mm)

|

Wall Thickness(mm)

|

Heat transfer area(m2/m3)

|

Opening ratio(%)

|

|

150*100*100

|

¢3.5

|

1

|

590

|

52

|

|

150*100*100

|

¢4.0

|

1.2

|

484

|

49

|

|

100*100*100

|

¢3.5

|

1

|

590

|

52

|

|

100*100*100

|

¢4.0

|

1.2

|

484

|

49

|

1. Honeycomb thermal storage has the advantages of large heat transfer area per unit volume, fast heat transfer, low airflow resistance, shallow heat transfer depth, and high thermal efficiency.

3. It has the advantages of high fire resistance, high load softening temperature, good slag resistance, good thermal shock stability, fast thermal conductivity, good erosion resistance, large capacity, and large heat capacity.

The ladle and intermediate ladle baking equipment adopts regenerative combustion technology: 1. The air can be preheated to above 1100 ° C, and low calorific value fuel can be used for smooth ignition and combustion, reducing production costs;

2. The exhaust temperature is only 150 ° C, and the waste heat from combustion flue gas is fully recovered, which can save energy by 30% to 50%;

3. High air preheating temperature, high combustion flame temperature, improved heat transfer performance inside the bag, and increased baking speed by 3-5 times;

4. Bake evenly, eliminate local high temperature points inside the ladle, and improve the service life of the steel ladle lining by about 15%;

5. Pollution emissions can be reduced by more than 50%;

Baking performance:

minutes, and the turnover package is around 30 minutes; New package: according to the baking curve.

automatically ignite the ladle.

extinguished, and can also send a signal to cut off the gas. Display the temperature of the ladle and send a prompt signal when it reaches the predetermined baking temperature.