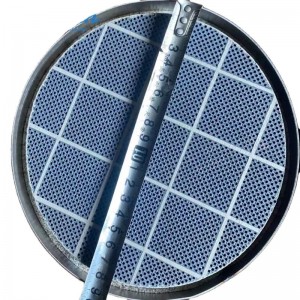

Infrared Honeycomb Ceramic Plate for burning

Infrared Honeycomb Ceramic Plate for burning

Infrared honeycomb ceramic combustion plate is the key component of infrared radiation burner. The performance will directly influence and determine the infrared burner energy-saving, environmental protection, health and economic performance.

|

Barbecues |

Gyro Cookers |

|

Broilers |

Pizza Ovens |

|

Convection Ovens |

Pressure Fryers |

|

Deep Fat Fryers |

Process |

|

Evaporators |

Ranges |

|

Gas Ovens |

Rotisserie Ovens |

|

Griddles |

Space Heaters |

|

Greenhouse CO2 |

Sear Cookers |

The products are mainly applied to combustion infrared burner, infrared gas stove, infrared heater.

(Barbecues Gyro Cookers Evaporators Ranges

Broilers Pizza Ovens Gas Ovens Rotisserie Ovens

Convection Ovens Pressure Fryers Griddles Space Heaters

Deep Fat Fryers Process Greenhouse CO2 Sear Cookers)

1. High mechanical Strength;

2. Large specific surface area;

3. Geometric size regular;

4. Uniform radiant burning;

5. Excellent thermal shock resistance;

6. Save up to 30~50% energy cost;

7. Burn without flame, high burning efficiency, low noise;

8. Has no carbon combustion channel non clogging;

9. Reduce the harmful gas such as CO, NOx, etc more than 90%.

● Outstanding Strength

● Uniform radiant burning

● Excellent thermal shock resistance

● Save up to 30~50% energy cost

● Burn without flame, high burning efficiency, low noise

● Reduce the harmful gas such as CO, NOx, etc more than 90%

|

Item |

Index |

|

Materials |

Cordierite |

|

Water Absorption |

50.4% |

|

Open Porosity |

61% |

|

Specific Gravity |

0.6-0.9g/cm3 |

|

Thermal Expansion Coefficient |

1.5-3(×10-6K-1) |

|

Temperature Softening |

>1280℃ |

|

Cooking Surface Temperature |

1000-1200℃ |

|

CO Release |

≤0.006% |

|

NOx Release |

≤5ppm |

|

Application |

Type |

Size |

| Oven Burner | RectanglePlum hole | 200x145x13mm,200x140x13mm,183x60x13mm,180x160,132x134x13mm,94x165x13mm,162x62x13mm |

| RectangleRhombus hole | 92x134x13mm,75x134x13mm,132x134x13mm,54x172x14mm,96x142x13mm,78x137x13mm,78x128x13mm | |

| RoundRhombus hole | Φ240,200,194,180,178,170,160,158,150,145,129,56mm | |

| Heater | Rectangle8 shape(mm) | 146x141x13mm,146x152x13mm,88x132x13mm,118x145x13mm,74x164x13mm,92x132x13mm,64x102x13mm,89x92x13mm,89x50x13mm |

| RectangleRhombus hole | 92x132x13mm,92x127x13mm | |

| RectanglePlum hole | 74x164x13mm,72x142x13mm |