OEM/ODM China Zir Ceramic Foam Filter - zirconia casting ceramic foam filter – Bestn

OEM/ODM China Zir Ceramic Foam Filter - zirconia casting ceramic foam filter – Bestn

OEM/ODM China Zir Ceramic Foam Filter - zirconia casting ceramic foam filter – Bestn Detail:

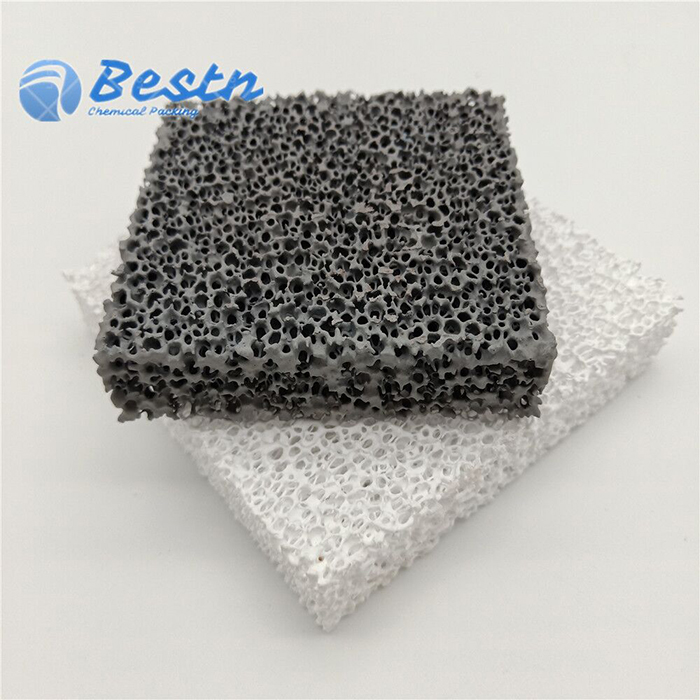

Zirconia Ceramic Foam Filter is a phosphate-free, high melting point, It is characterized by high porosity and mechanochemical stability and excellent resistance to thermal shock and corrosion from molten steel, It can effectively remove inclusions, reduce trapped gas and provide laminar flow when molten zirconia foam filtrated, it is machined to tight dimensional tolerance during production, this combination of physical properties and precise tolerance make them first choice for molten steel,alloy steel, and stainless steel, etc.

|

Dimensions (mm) |

Zirconia Foam Filter |

|

|

Pouring Rate(kg) |

Filtration Capacity(kg) |

|

|

50×50×22 |

3~5 |

30 |

|

50×75×22 |

4~6 |

40 |

|

75×75×22 |

7~12 |

60 |

|

75×100×22 |

8~15 |

80 |

|

100×100×22 |

14~20 |

100 |

|

Dia 50×22 |

2~6 |

18 |

|

Dia 80×22 |

6~10 |

50 |

|

Dia 90×22 |

8~16 |

70 |

1.Filter out the inclusions in the casting, reduce the gas in the casting, reduce the degree of turbulence during

the flow filling of the metal, reduce the surface defects in the casting, and significantly reduce the rejection rate of the casting.

2.Improve the fluidity of molten metal, increase the filling ability and shrinkage ability of the casting, improve

the surface finish of the casting, increase the compression seal of the casting, enhance the elongation and tensile strength, and improve the surface quality and mechanical properties of the casting.

3.It has very high temperature working strength, chemical stability, thermal shock resistance and resistance to metal liquid flow impact. High chemical stability makes it not affected by the acidity and alkalinity of the molten metal and does not change the chemical composition of the molten metal. There is no slag dropping or cracking in the work, which ensures the filtration quality of molten metal and the stability of chemical composition.

4.It has a large metal flow rate, and the flow rate is stable (different from the straight hole ceramic filter, the flow rate gradually decreases with the increase in the number of captured impurities). Its filtering effect is

much higher than that of other filter elements.

5.It has very high dimensional accuracy and can be used in the production line for automatic filter placement.

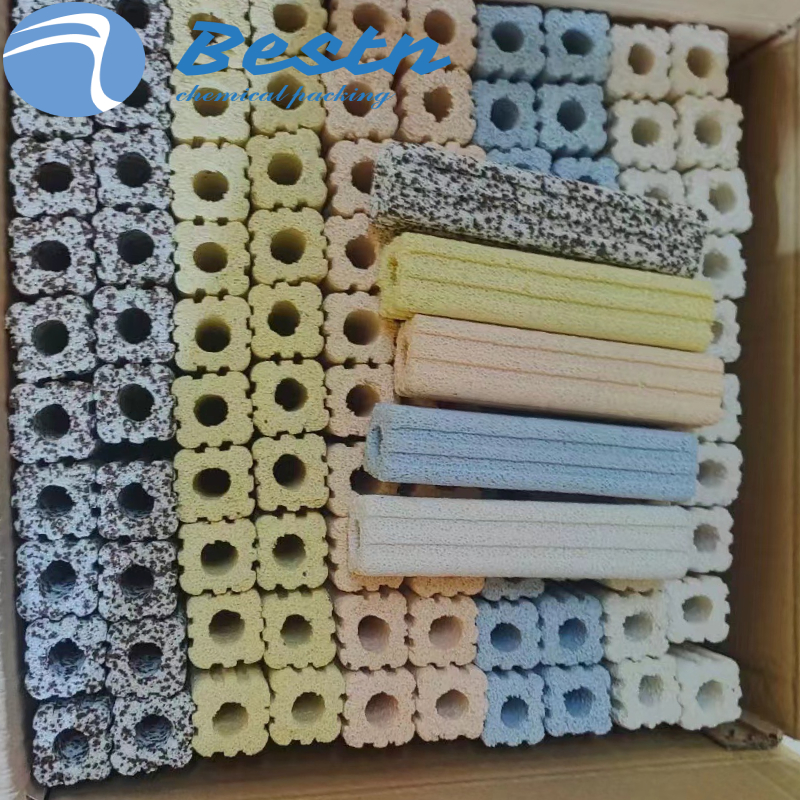

Product detail pictures:

Related Product Guide:

It adheres to the tenet "Honest, industrious, enterprising, innovative" to develop new products constantly. It regards customers, success as its own success. Let us develop prosperous future hand in hand for OEM/ODM China Zir Ceramic Foam Filter - zirconia casting ceramic foam filter – Bestn , The product will supply to all over the world, such as: Egypt, Costa Rica, Spain, We have now a good reputation for stable quality goods, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!