High Quality Honeycomb Ceramic Substrate - Honeycomb Ceramic Plate for casting and gas filter – Bestn

High Quality Honeycomb Ceramic Substrate - Honeycomb Ceramic Plate for casting and gas filter – Bestn

High Quality Honeycomb Ceramic Substrate - Honeycomb Ceramic Plate for casting and gas filter – Bestn Detail:

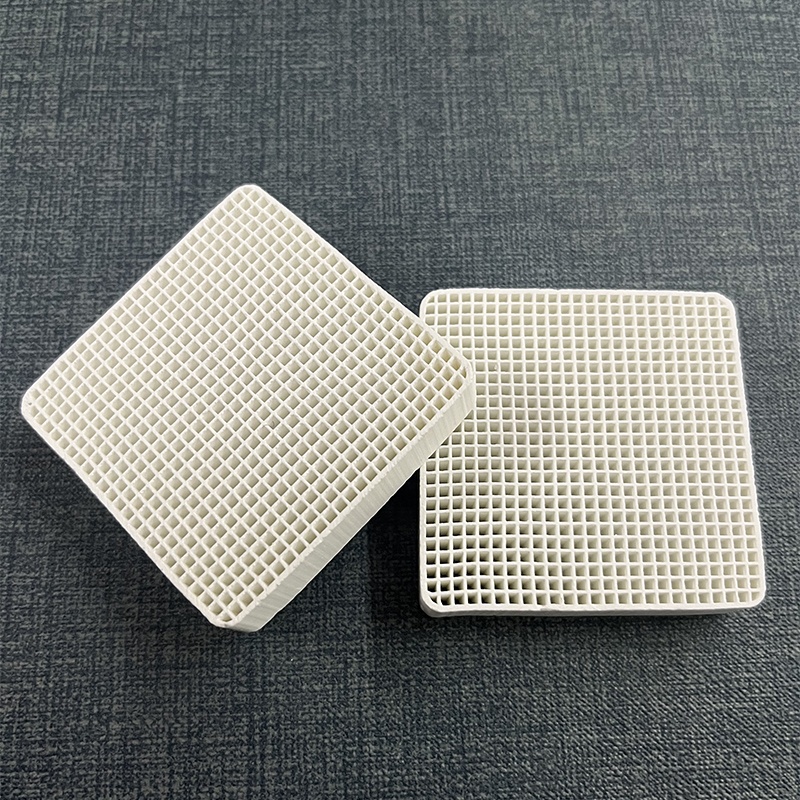

Technology: Extruded.

Pore density: 100PCSI, 200PCSI, 300PCSI, etc.

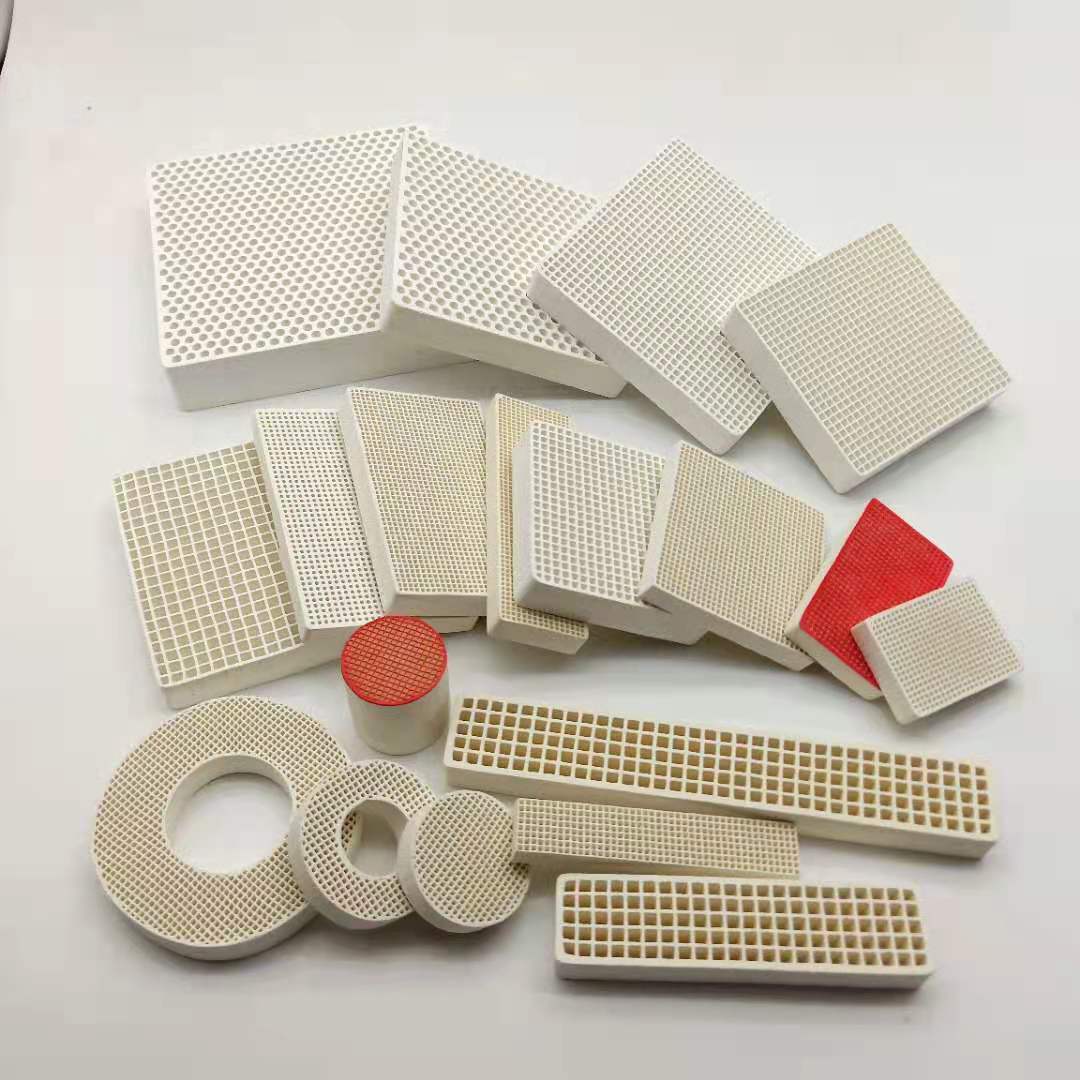

Cell shape: Square, round, hexagon, triangle.

Available range of size: 25 mm to 200 mm.

Available range of thickness: 12 mm to 22mm or as per client’s requirements.

Appearance shape: Round, square and rectangle

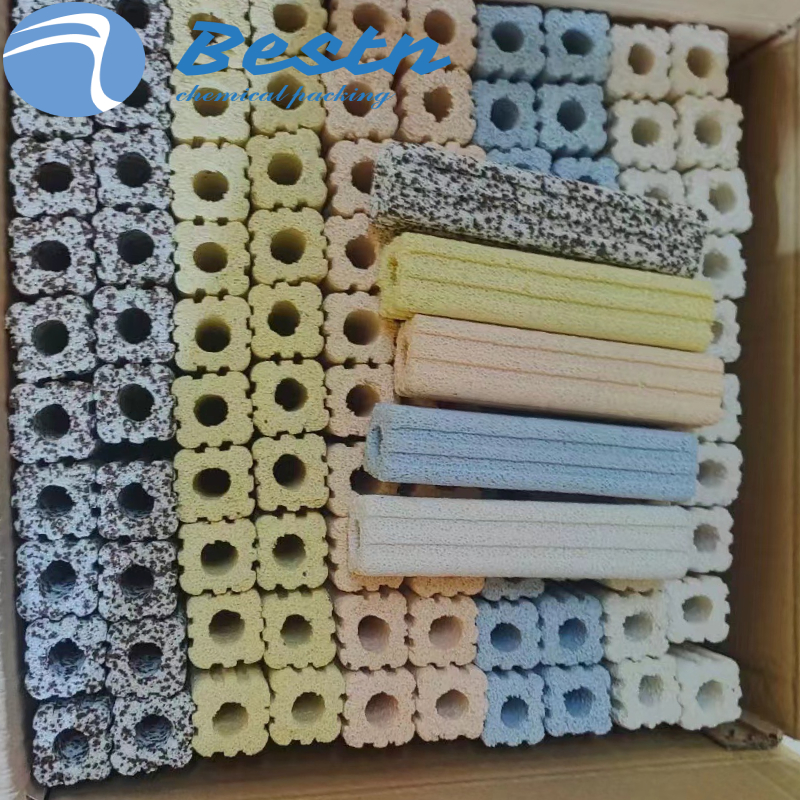

Material: Cordierite, mullite, corundum mullite, zircon mullite, zirconia-corundum, high aluminum, silicon carbide and etc.

Maximum working temperature: 1350°C, 1500°C, 1600°C, 1650°C.

Application: Grey iron, ductile iron and malleable iron, aluminum, aluminum alloy, copper, stainless steel and so on.

1: used in towers of petrochemical, fertilizer and environment protection industries.

2: various separation,absorption and desorption equipment,normal atmospheric pressure reduced and vacuum distillation plant,decarburateing and desulfuration systems,ethyl benzene separation,and Iso-octane/toluene systems.

Infrared honeycomb ceramic plate

Infrared honeycomb ceramic combustion plate is the key component of infrared radiation burner. The performance will directly influence and determine the infrared burner energy-saving, environmental protection, health and economic performance.

The products are mainly applied to combustion infrared burner, infrared gas stove, infrared heater.

(Barbecues Gyro Cookers Evaporators Ranges

Broilers Pizza Ovens Gas Ovens Rotisserie Ovens

Convection Ovens Pressure Fryers Griddles Space Heaters

Deep Fat Fryers Process Greenhouse CO2 Sear Cookers)

1. High mechanical Strength;

2. Large specific surface area;

3. Geometric size regular;

4. Uniform radiant burning;

5. Excellent thermal shock resistance;

6. Save up to 30~50% energy cost;

7. Burn without flame, high burning efficiency, low noise;

8. Has no carbon combustion channel non clogging;

9. Reduce the harmful gas such as CO, NOx, etc more than 90%.

|

Barbecues |

Gyro Cookers |

|

Broilers |

Pizza Ovens |

|

Convection Ovens |

Pressure Fryers |

|

Deep Fat Fryers |

Process |

|

Evaporators |

Ranges |

|

Gas Ovens |

Rotisserie Ovens |

|

Griddles |

Space Heaters |

|

Greenhouse CO2 |

Sear Cookers |

● Outstanding Strength

● Uniform radiant burning

● Excellent thermal shock resistance

● Save up to 30~50% energy cost

● Burn without flame, high burning efficiency, low noise

● Reduce the harmful gas such as CO, NOx, etc more than 90%

|

Item |

Index |

|

Materials |

Cordierite |

|

Water Absorption |

50.4% |

|

Open Porosity |

61% |

|

Specific Gravity |

0.6-0.9g/cm3 |

|

Thermal Expansion Coefficient |

1.5-3(×10-6K-1) |

|

Temperature Softening |

>1280℃ |

|

Cooking Surface Temperature |

1000-1200℃ |

|

CO Release |

≤0.006% |

|

NOx Release |

≤5ppm |

|

Application |

Type |

Size |

| Oven Burner | RectanglePlum hole | 200x145x13mm,200x140x13mm,183x60x13mm,180×160,132x134x13mm,94x165x13mm,162x62x13mm |

| RectangleRhombus hole | 92x134x13mm,75x134x13mm,132x134x13mm,54x172x14mm,96x142x13mm,78x137x13mm,78x128x13mm | |

| RoundRhombus hole | Φ240,200,194,180,178,170,160,158,150,145,129,56mm | |

| Heater | Rectangle8 shape(mm) | 146x141x13mm,146x152x13mm,88x132x13mm,118x145x13mm,74x164x13mm,92x132x13mm,64x102x13mm,89x92x13mm,89x50x13mm |

| RectangleRhombus hole | 92x132x13mm,92x127x13mm | |

| RectanglePlum hole | 74x164x13mm,72x142x13mm |

Product detail pictures:

Related Product Guide:

Reliable quality and good credit standing are our principles, which will help us at a top-ranking position. Adhering to the tenet of "quality first, customer supreme" for High Quality Honeycomb Ceramic Substrate - Honeycomb Ceramic Plate for casting and gas filter – Bestn , The product will supply to all over the world, such as: Borussia Dortmund, Melbourne, Moscow, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.